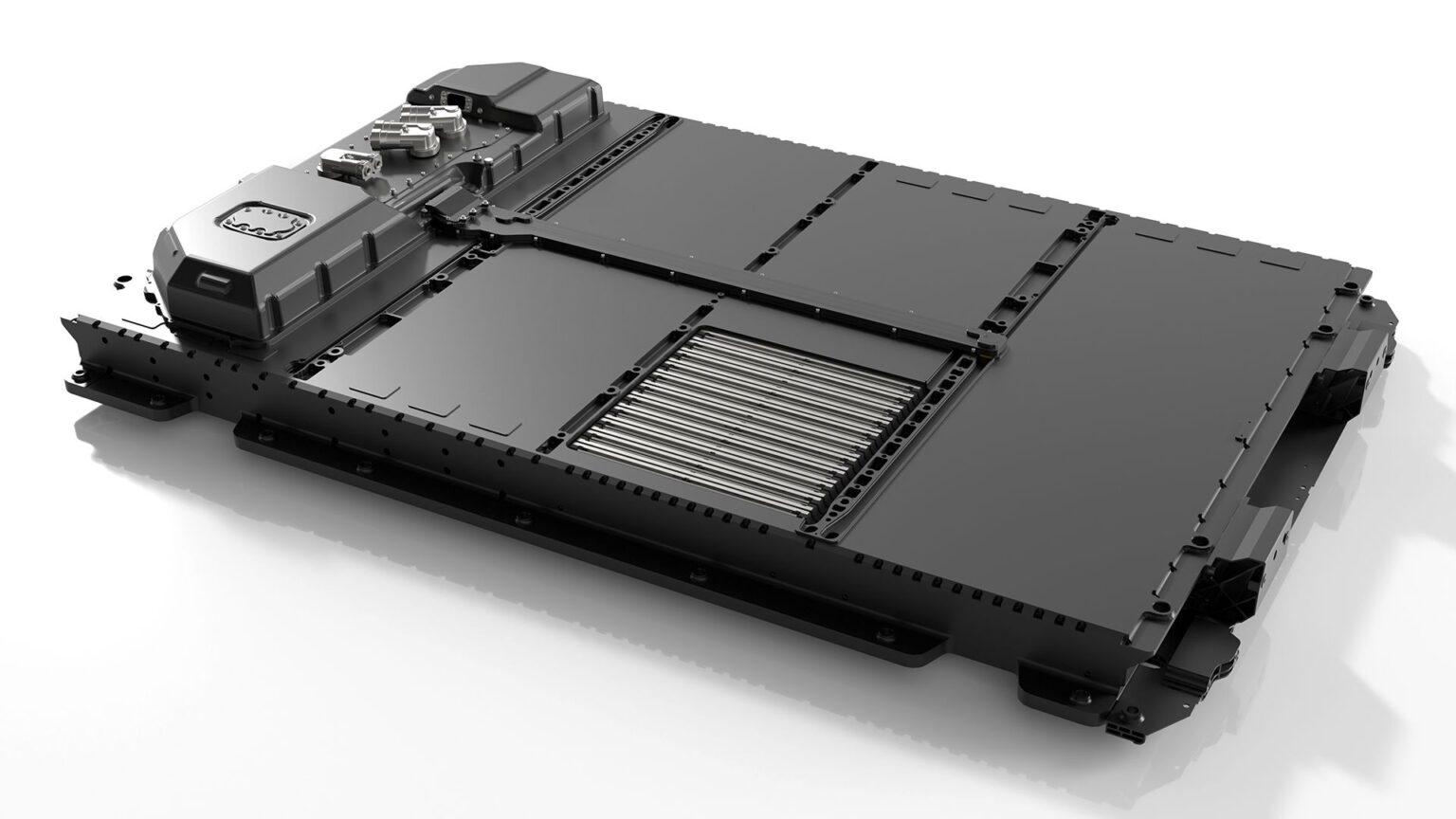

Solid-state batteries have often been described as the holy grail of energy storage. In electric vehicles, this technology promises longer range, faster charging, and much greater safety, huge upsides that could revolutionize personal transportation. Numerous companies – automakers, supplier firms, and academics alike – are scrambling to develop economically viable, mass-producible solid-state batteries to power the future, but all these efforts may be wasted.

Not Necessarily A Big Difference

According to a report from Interesting Engineering, this technology may not deliver what has been promised, at least compared to lithium-ion batteries currently in production. “A study evaluating garnet-type solid electrolytes, specifically lithium lanthanum zirconium oxide (LLZO),” the article states, “has indicated that the anticipated energy density benefits of solid-state lithium-metal batteries might be overstated.” Well, that’s disappointing.

Reportedly, that LLZO chemistry achieves an energy density of around 272 Watt-hours per kilogram. In comparison, existing lithium-ion batteries are rated anywhere between 250 and 270 Wh/kg, a potential difference of as little as 0.74 percent, which is negligible, especially when the cost and manufacturing issues of solid-state technology are considered.

The LLZO chemistry could be a viable solution for solid-state batteries, but there are other challenges. Interface voids and the formation of dendrites inside the batteries – tree-like structures that grow and can cause a cell to short out – are huge challenges, as is the inherent brittleness of this design, which makes manufacturing components that are free of defects a serious challenge.

One potential solution to those issues is to adopt a hybrid design, one that incorporates “LLZO-in-polymer composite electrolytes.” This can make the manufacturing process easier while maintaining ionic conductivity. Quasi-solid-state electrolytes are also a potential option. These incorporate small amounts of liquid electrolyte, which provides structural integrity with enhanced ionic transport.

Are Solid-State Batteries Still The Future?

Despite these potential issues, numerous companies are still working on solid-state batteries. Mercedes-Benz is developing the technology, which could deliver comparable electric vehicle range with a whopping 40-percent reduction in weight compared to current nickel-manganese-cobalt battery designs.

Similarly, researchers at the Andlinger Center for Energy and the Environment at Princeton University are working on a solid-state battery design that does not contain anodes. This could make the packs smaller and cheaper to manufacture, two major pluses.

Hyundai and Kia are developing new battery designs, too, though researchers acknowledge the inherent challenges. It sounds like they won’t be able to commercialize solid-state batteries before the year 2030.

Despite these difficulties – and others – this technology could revolutionize electric vehicles in the future. Automakers, suppliers, and academics are unlikely to stop researching solid-state batteries anytime soon, and hopefully they figure out how to address the shortcomings of this energy-storage design.

Read the full article here